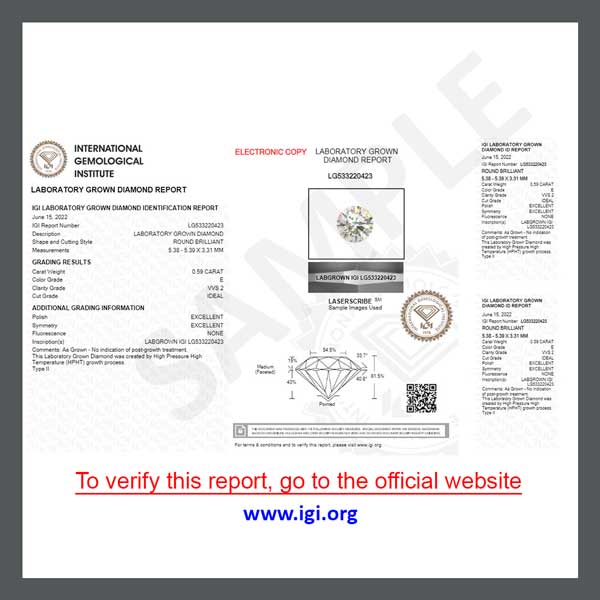

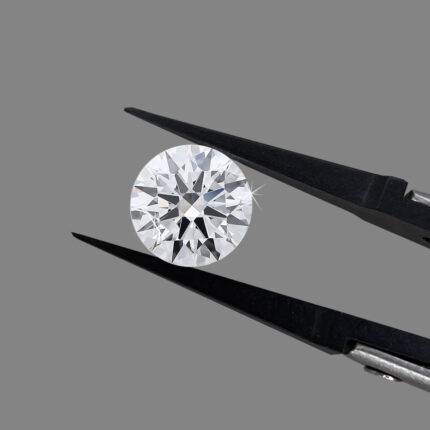

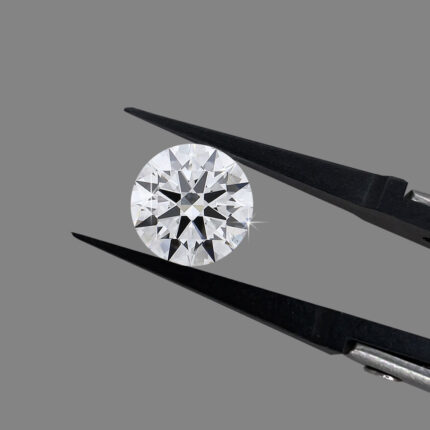

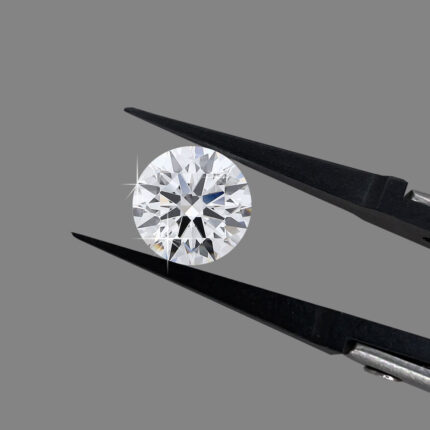

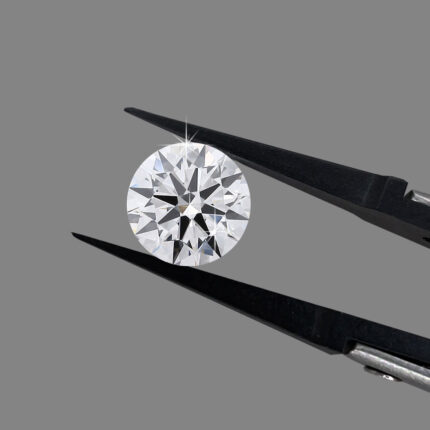

0.73 Carat HPHT OVAL shape lab grown diamond D VS2 IGI Certified

₹22000 ex. gst

Key Details :-

Diamond Type : Lab Grown Diamond

Shape & Cut : OVAL

Carat Weight : 0.73 Carat

Color Grade : D

Clarity Grade : VS2

The HPHT method is capable of producing high-quality, type IIa diamonds, which are typically of exceptional purity and transparency.

Check all details in the Additional Information tab below-

Please note :- It is advisable to carefully review the terms and conditions, privacy policy and return and refund before making a purchase from our website.

COPY THE GREEN CODE AND VERIFY FROM OFFICIAL WEBSITE www.igi.org 506189336

| Diamond Type |

Lab Grown Diamond |

|---|---|

| Certificate Type |

IGI |

| Shape & Cut |

Oval |

| Weight Category |

Below 1 carat |

| Measurement |

7MM |

| Color |

D |

| Clarity |

VS2 |

| Cut |

Excellent |

| Polish |

Very Good |

| Symmetry |

Very Good |

| Girdle Thickness |

Medium to slightly thick |

| Treatment |

Type IIA (2A) |

| Manufactured in |

MUMBAI |

| Brand |

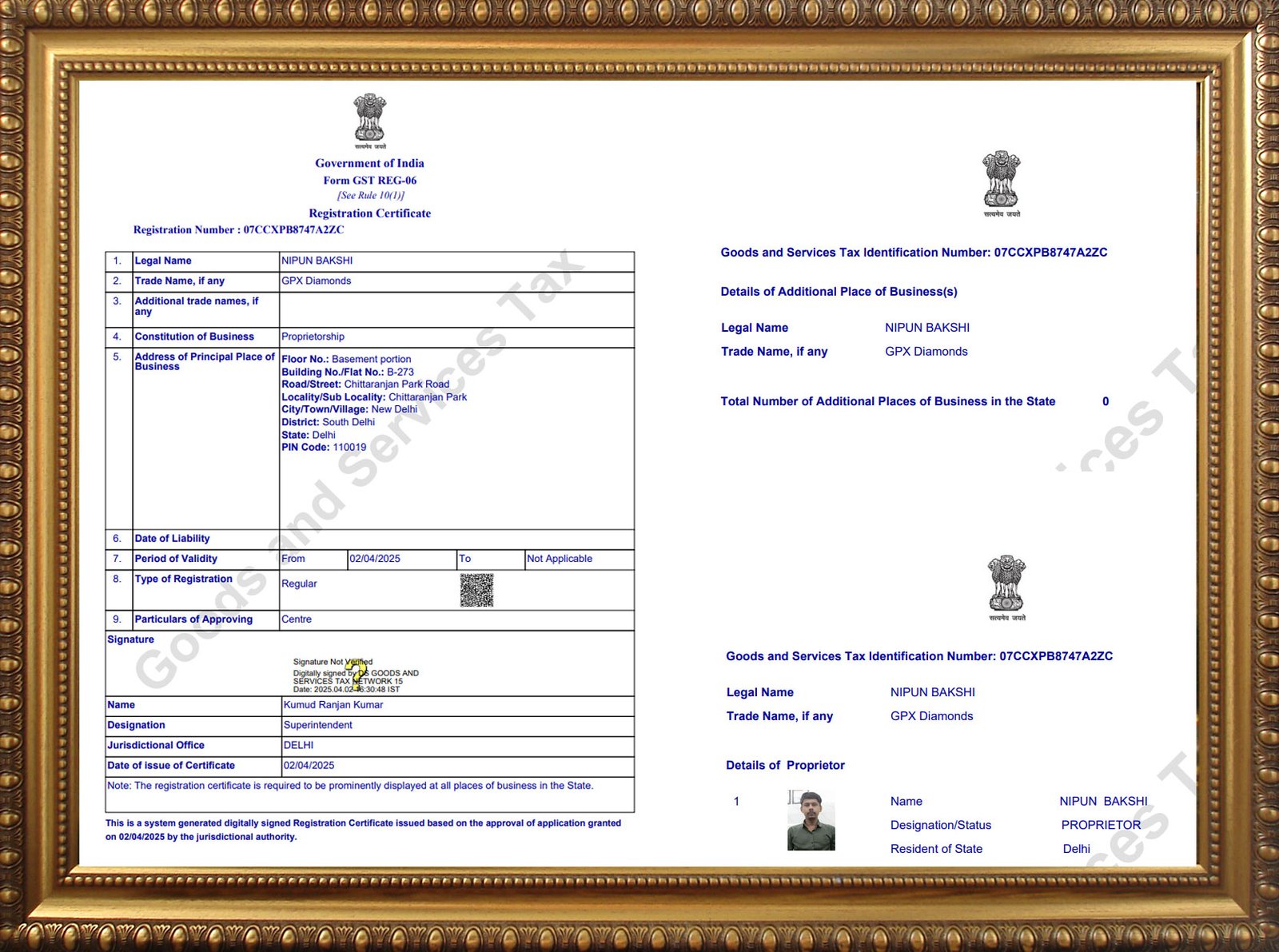

GPX Diamonds |

| 100% COD Payment | Open Box Delivery |

100% Secure Payment

9

People watching this product now!

SKU:

YDT-7724_506189336

Categories: All, HPHT Diamonds, HPHT Oval Diamond

Tags: Certified Diamond, Diamond seller, Lab grown diamond

Description

The High Pressure High Temperature (HPHT) diamond making process is one of the methods used to create synthetic or lab-grown diamonds. Here are the key steps in the HPHT diamond-making process:

Seed Crystal Selection: The process begins with the selection of a small natural diamond fragment or a synthetic diamond “seed.” This seed crystal will serve as the foundation for the new diamond’s growth.

High Pressure Chamber: The selected seed crystal is placed in a high-pressure chamber along with carbon source material, typically graphite. The chamber is then sealed to create a controlled environment.

High Temperature and Pressure: The sealed chamber is subjected to extreme conditions of high pressure and high temperature, mimicking the natural conditions under which diamonds form deep within the Earth’s mantle. Pressures can range from 725,000 to 1.2 million pounds per square inch (psi), and temperatures can reach over 2,200 degrees Celsius (3,992 degrees Fahrenheit).

Carbon Dissolution: Under these extreme conditions, the carbon source material begins to dissolve into a molten state.

Diamond Growth: The carbon in the molten state is attracted to the seed crystal. Carbon atoms are added layer by layer to the seed crystal, slowly growing a synthetic diamond.

Cooling and Pressure Release: After the desired diamond size is achieved, the chamber is gradually cooled, and the pressure is released. This process can take several days to complete.

Removal and Cutting: The grown diamond, which is still rough and uncut, is then removed from the chamber. It may undergo cutting and polishing processes to shape it into a marketable gem.

|

|

|

|

Reviews (0)

Rated 0 out of 5

0 reviews

Rated 5 out of 5

0

Rated 4 out of 5

0

Rated 3 out of 5

0

Rated 2 out of 5

0

Rated 1 out of 5

0

Be the first to review “0.73 Carat HPHT OVAL shape lab grown diamond D VS2 IGI Certified” Cancel reply

Shipping & Delivery

Domestic Shipping

For orders within the same country as our distribution center, we offer reliable and secure shipping services. Your lab grown diamond will be carefully packaged to guarantee its safety during transit. Delivery time may vary depending on your location but our primarily shipping and delivery time ranges from 2 to 5 days, and we strive to process and dispatch orders as quickly as possible.

International Shipping

GPX Diamonds proudly serves customers around the globe. Our international shipping is designed to bring the brilliance of lab grown diamonds to your location, no matter where you are. International shipping times may vary due to customs procedures and the destination country’s regulations but primarily our global shipping typically ranges between 7 to 25 days. Rest assured, we work diligently to minimize any potential delays and ensure a smooth delivery process.

Related products

3.01 Carats Lab Grown Diamond G,SI1 Clarity

Rated 5.00 out of 5

(4)

Best Price 1ct Diamond Round cut (1.03) IGI certified – GPX Diamonds

Rated 4.67 out of 5

(6)

Super 1.50 Carat Circle Diamond F Si1 Lab Diamond

Rated 5.00 out of 5

(4)

1.24 Carat Solitaire Lab grown Diamond E VS1 Grown Diamond

Rated 4.75 out of 5

(4)

2 Carat lab grown diamond (2.08ct) | Round cut IGI Certified

Rated 4.78 out of 5

(9)

Best 1 carat Emerald cut diamond for jewelry E VS1

Rated 5.00 out of 5

(3)

0.50 carat Lab Made Emerald cut diamond F VS1 clarity

Rated 5.00 out of 5

(3)

2 Carat Single Diamond Brilliant Round Cut (2.01ct)

Rated 5.00 out of 5

(4)

Reviews

Clear filtersThere are no reviews yet.